Steel Fiber Reinforced Polyethylene Wear-Resistant Composite Pipe

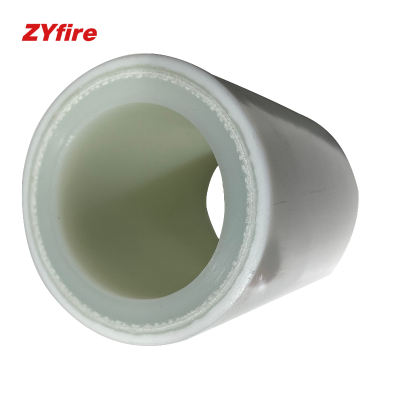

The inner pipe material, extruded with polyolefin wear-resistant material and polyethylene, provides exceptional wear resistance.

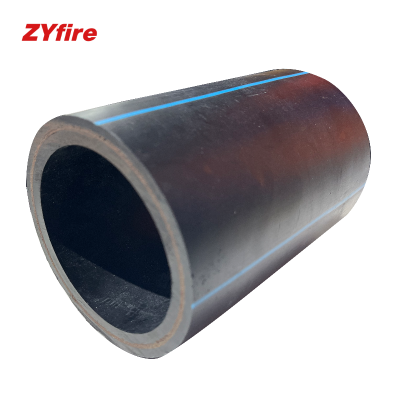

As a bonded-type pipe, it features a stable composite structure with uniform stress distribution and high load-bearing capacity, delivering superior performance in high-pressure resistance, high-temperature resistance, low expansion, and creep resistance.

This product is primarily designed for long-distance slurry transport, coal slurry transport in power plants, tailings slurry transport, and solid-liquid two-phase transport applications.

Details

Product Characteristics

The inner pipe material, extruded with polyolefin wear-resistant material and polyethylene, provides exceptional wear resistance.

As a bonded-type pipe, it features a stable composite structure with uniform stress distribution and high load-bearing capacity, delivering superior performance in high-pressure resistance, high-temperature resistance, low expansion, and creep resistance.

This product is primarily designed for long-distance slurry transport, coal slurry transport in power plants, tailings slurry transport, and solid-liquid two-phase transport applications.

Product Advantages

High Pressure Resistance: Withstands pressures ranging from 1.6MPa to 32MPa at room temperature.

Excellent Wear Resistance: The wear-resistant layer, extruded with polyolefin wear-resistant material and polyethylene material, provides strong anti-wear capabilities.

Corrosion Resistance: Polyethylene has a saturated molecular structure, offering good chemical stability and resistance to various corrosive media, with dual-sided anti-corrosion properties.

Good Flexibility: The wear-resistant layer, extruded with polyolefin wear-resistant material and polyethylene material, provides strong anti-wear capabilities.

Low Expansion Coefficient: The steel fibers are fused with the pipe, resulting in a low expansion coefficient at high temperatures and minimal deformation.

Easy Installation: Reliable joint connections, with various connection options available for different working conditions, offering high cost-effectiveness.

Application Scope

Suitable for oil and gas fields, energy, mining, chemical industries, and other sectors, transporting media including multiphase fluids, gaseous hydrocarbons, liquid hydrocarbons, chemicals, non-potable water, slurry, fly ash, brine, and more.

Installation Methods: Buried below frost layer or surface-laid.

FAQ

Q: Are you a factory or trading company?

A: We are a professional RTP manufacturer.

Q: What can you supply?

A: We could provide perfect fluid transmission for the world.

Q: Can you produce goods with special specification?

A: Yes, we can.

Q: What is your MOQ?

A: Our MOQ varies with different products.

Q: Can you send us a sample to test before ordering?

A: We are honored to offer you samples.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)